|

|

CONTINUOUS |

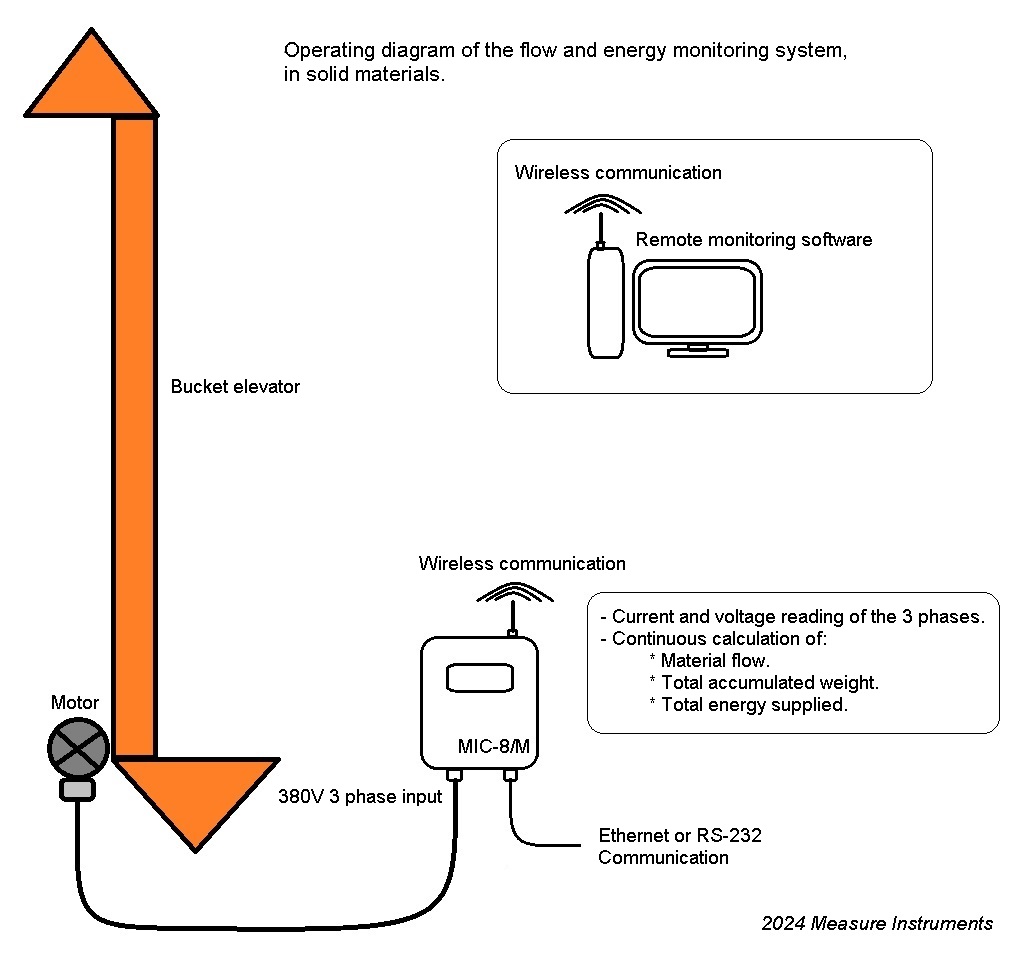

CONTINUOUS FLOW MEASUREMENT IN SOLID MATERIALS

Monitoring in bucket elevators for grains, cereals, flours, minerals, powders and granules. Energy efficiency system.

|

|

SYSTEM CARACTERISTICS

- MIC-8/M Continuous measurement of flow of solid materials in motion, flowmeter. - Permanent monitoring of current and voltage in motors involved in the movement of the material. - Calculation of the flow and weight of accumulated material, during the process, based on complex algorithms, based on the energy supplied. - Applications: monitoring and control in the grain drying process, flour production, bucket elevators of granular materials or powders, bucket conveyors, mining, movement or elevators of minerals or solids. ENERGY EFFICIENCY - Option to calculate the total energy supplied to the motor, in kWh, during the entire process or operating period and the relationship between tons processed and energy, in kWh/Tn. OPTIONAL - Development of specific additional functions, according to the characteristics of each process, granulometry of the material, circulation mode, environment and measurement needs. FEATURES OF THE MIC-8/M HEAD - Equipped with current and voltage reading modules for the 3 phases in 380V motors. - Configurable and expandable inputs, for monitoring and calculating flow in more than one motor. - Alphanumeric display with LED matrix, high luminosity, both at low and high temperatures. - 2 levels of operation: - Basic level: to start or stop the process. - With access code: for programming calibrations and configuring operating and display parameters. - During the process it indicates: flow rate in Kg/sec. o Configurable Tn/hr and Kgs accumulated from the beginning of each process or batch of material. - Ethernet and RS-232 communication output, for remote monitoring and programming of configuration parameters and calibrations. - Remote monitoring software, data recording, display of values and graphs of the evolution of the process, on the screen of a PC. - Additional software for managing and storing calibrations on the computer, as a backup and for adjusting readings. - Power: 220 VAC. - Head made of metal, IP65, with glass cover. |

Es

Es De

De